How Efficient Welding Examination Improves Architectural Honesty and Long Life

In the realm of building and design, the importance of welding assessment can not be overstated, as it plays a critical function in making certain structural integrity and prolonging the life expectancy of tasks. By releasing a range of sophisticated evaluation methods, such as radiographic and ultrasonic screening, professionals can determine issues that might compromise the reliability of a structure. Nevertheless, the concern stays: exactly how do these thorough procedures equate right into concrete advantages for durability and safety? Join the exploration of how reliable welding examinations can change prospective vulnerabilities right into toughness, adding to the enduring success of constructions.

Value of Welding Evaluation

Making certain the architectural integrity and security of welded buildings requireds strenuous welding inspection processes. Welding inspection serves as an essential protect in the building and production markets, where the stamina and toughness of joints dramatically influence the total efficiency of structures.

In enhancement to safety, welding examination plays an important duty in high quality guarantee. Sector requirements and codes, such as those from the American Welding Society (AWS) or the International Organization for Standardization (ISO), require adherence to rigorous standards, underscoring the value of examinations in fulfilling these expert and lawful commitments.

Trick Inspection Strategies

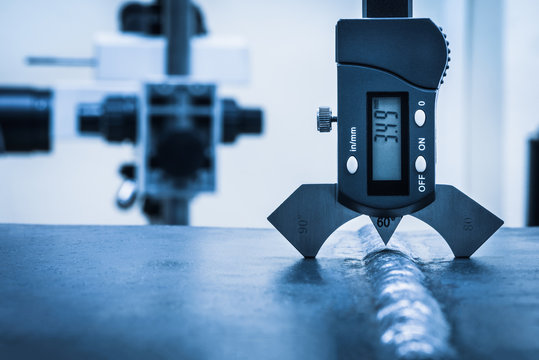

Ultrasonic Testing (UT) uses high-frequency sound waves to detect subsurface imperfections, using precise information regarding weld stability without causing any kind of damage. Radiographic Examining (RT), including X-rays or gamma rays, provides a thorough picture of the weld's internal structure, disclosing concealed imperfections. Magnetic Bit Examining (MPT) is one more non-destructive approach, especially reliable for finding surface and near-surface stoppages in ferromagnetic products.

Penetrant Screening (PT) includes the application of a fluid color to expose surface-breaking issues, providing a uncomplicated and affordable service for non-porous products. Each strategy has its specific applications, strengths, and restrictions, and usually a combination of techniques is employed to achieve detailed assessment outcomes. Proficiency of these strategies enhances the reliability and sturdiness of bonded frameworks, straightening with safety and security and efficiency assumptions.

Identifying Common Issues

Porosity, characterized by gas pockets within the weld, reduces the weld's strength and toughness. Splits, which can take place during or after welding, position substantial threats due to their potential to propagate under tension.

Incomplete fusion, where the weld metal fails to bond completely with the base product, undermines the architectural stability, leading to weak joints. Slag inclusions take place when non-metallic materials are trapped in the weld, endangering its stamina and quality.

Recognizing these flaws through thorough assessment methods, such as aesthetic evaluation, ultrasonic screening, or radiography, is important. Addressing these problems guarantees weld top quality, eventually sustaining the structural honesty and safety and security of the built atmosphere.

Enhancing Structural Efficiency

Understanding the significance of determining typical weld flaws naturally results in exploring methods for boosting architectural performance. The fundamental strategy for enhancing performance entails using innovative welding methods and materials that reduce defect occurrence. Making use of high-grade filler products and making sure appropriate warm control can considerably minimize concerns such as porosity and fracturing, consequently improving the weld's integrity.

Incorporating state-of-the-art welding technologies, such as laser welding and rubbing stir welding, more magnifies structural strength. These techniques supply remarkable precision and decreased thermal distortion, directly affecting the resilience and toughness of the welded frameworks. Furthermore, taking on automated welding systems can guarantee repeatable and constant weld top quality, reducing human mistake.

Furthermore, applying rigorous pre-weld and post-weld procedures is vital. Correct joint design, surface prep work, and stress-relieving procedures add to optimal weld efficiency. Performing comprehensive pre-weld examinations allows for early detection of possible concerns, helping with timely improvements before they endanger the framework.

Long-term Benefits of Examination

With cautious assessment techniques, the long-term advantages to structural honesty become progressively noticeable. Extensive and regular welding inspections play a vital function in stopping structural failures by identifying click here to find out more problems and inconsistencies early in the building and construction procedure. This positive approach ensures that possible problems are Find Out More addressed prior to they can compromise the safety and security and resilience of structures. By capturing flaws early, expensive repairs and downtime are decreased, eventually extending the life expectancy of the infrastructure.

In addition, regular evaluations add to keeping conformity with industry requirements and guidelines, therefore avoiding legal and monetary effects. This adherence to quality control not only enhances the dependability of the structure however additionally cultivates trust fund amongst stakeholders, consisting of customers, designers, and regulatory bodies. The comprehensive documentation of evaluation results serves as a useful source for future upkeep and repair service initiatives, promoting educated decision-making.

Furthermore, efficient assessment methods support development by incorporating advanced technologies such as non-destructive screening and electronic imaging, which can improve accuracy and performance. This technological assimilation additionally emphasizes the commitment to excellence in architectural honesty. Inevitably, buying precise welding evaluations is a sensible approach that produces substantial lasting advantages, protecting both the physical and financial financial investment in infrastructure tasks.

Final Thought

Effective welding inspection plays a crucial duty in improving architectural stability and longevity by recognizing flaws early in the construction procedure. Utilizing strategies such as visual inspection, ultrasonic screening, and radiographic screening makes sure the detection of concerns like fractures and porosity that jeopardize weld toughness. Extensive evaluations ensure conformity with industry criteria, consequently prolonging the life-span of frameworks, reducing costly fixings, and promoting stakeholder trust fund in the reliability and security of bonded go to this site constructions.

In the world of building and construction and engineering, the value of welding inspection can not be overemphasized, as it plays a crucial role in guaranteeing architectural honesty and extending the life expectancy of tasks.Making certain the structural stability and safety and security of bonded constructions mandates extensive welding evaluation procedures.Structure upon the significance of welding evaluation in securing architectural honesty, understanding the essential assessment strategies becomes necessary for effective implementation. Efficient welding assessment incorporates an array of techniques created to review weld quality, ensuring compliance with stringent engineering standards - Welding Inspection Madison.Efficient welding assessment plays a critical duty in boosting architectural stability and longevity by identifying issues early in the building and construction procedure

Comments on “Essential Tips for Effective Welding Inspection Madison Providers”